News

Jul 23,2021

Customer Experience First | Diversified One-stop Services Escorts Smart Logistics

Logistics Equipment Industry Extends From Manufacturing to Servitization

In recent years, with the development of smart logistics, the informatization, intellectualization and digitization level of logistics system are continuously improving, the stock scale of automatic logistics system is increasing, and the demand of market customers for supporting integrated logistics equipment services is growing rapidly, which provides space for logistics equipment enterprises to launch engineering technical services to show its talent, promote the extension of logistics equipment industry chain from the core of manufacturing to service.

At present, the development mode of domestic logistics equipment service is divided into three parts: pre-sales, in-sales and after-sales. Pre-sales includes project consultation, scheme planning and design, product selection guide, customized function development, construction planning and design, etc; In sale services include product transportation, system installation and commissioning, technical training, etc; The after-sales service includes emergency maintenance, preventive maintenance, supply of spare parts and consumables, in plant service, accompanying production during peak hours, asset management, operation guarantee, technology support, equipment relocation, upgrading, training and consulting services and other content.

Realize Its Potential: It Is Time to Show Real Service

After 20 + years of service accumulation for the industry's leading customers, Damon Technology has formed a good project service system. Each service engineer of Damon has a full understanding of the company's products, has rich project service experience and professional skills, and can provide customers with real-time, fast, professional and efficient one-stop services.

Consulting Planning

The service is divided into four steps: preliminary planning preparation, project field investigation, design data analysis, scheme preparation and output. Damon's logistics experts will understand the basic status of the project according to the site conditions of the project site, customers' efficiency requirements and other needs for the system, as well as the future benefits that the system can bring, so as to formulate efficient personalized system solutions for customers and provide high-quality consulting services.

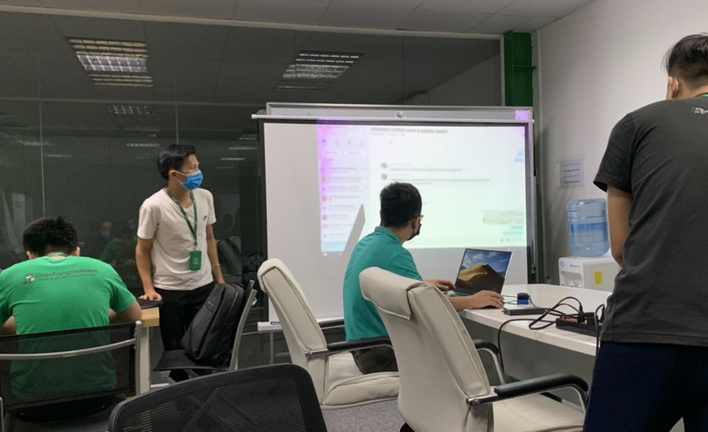

Technical Support and Training

Provide theoretical and practical operation training for equipment operation and maintenance personnel, evaluate skills according to different situations of individuals and teams, and arrange professionals to provide customized training plans and services for customers. Through theoretical training, customers can fully understand the structure, function and operation of the system; Through practical operation training, customers can quickly master the operation and use of equipment and the daily maintenance of equipment, and can improve the rapid handling ability of operators and equipment maintenance personnel to equipment faults.

Telephone Technical Guidance

Customers can quickly contact the technical support personnel by calling the 7 * 24-hour 400-065-1968 service hotline 24 hours a day to ensure that customers' problems can be responded to in time at any time. After receiving the customer's technical support request or fault repair report, it will immediately learn the details of the equipment / system fault from the customer, and guide the customer to solve the problem by telephone. In case of technical problems that cannot be solved immediately, it will be entered into the customer reporting system, and the customer will be informed of the expected completion time of treatment.

Remote Intelligent Service

Use AR and other modern technologies to realize remote linkage, diagnose software and hardware faults on the project site, guide customers to solve product use problems, and assist in identifying the quality of spare parts. Minimize unplanned equipment downtime, improve system online rate and overall efficiency. Coordinate the docking work of on-site personnel, follow up problems and summarize remote technical support reports, establish remote diagnosis case base, fault experience base and technical guidance manual, and constantly improve the remote service process.

Emergency Maintenance

The emergency response mechanism of the equipment can ensure the rapid, accurate and effective organization of emergency repair in case of failure, minimize the shutdown loss and reduce the maintenance cost.

Maintenance

Carry out preventive maintenance on the hardware, electric control and software of the equipment system to maintain the equipment performance and improve the system operation status. And put forward improvement suggestions for customers' use and maintenance of equipment according to the maintenance situation.

On-site Service

Damon's experienced on-site service team conducts specific evaluation of the project according to customer requirements, provides effective mechanical, software and hardware support on site, and keeps the system running smoothly. When the system has a problem, judge the trouble range at the first time, respond and deal with it in the shortest time, and reduce the time cost of trouble resolution.

Accompany Production During Peak Period

Aiming at the period of 618 Festival, Double 11 Event, Damon professional engineers will escort the operation of customers' equipment. It can deal with the problems of the equipment on the project site in real time, ensure the rapid solution of the problems, ensure the stable operation of the equipment, and improve the production efficiency in the peak period of customers.

Preventive Maintenance

In the daily operation of system, use IoT technology and data analysis to predict the future problems that may occur in the process of operation, through the provision of system security check, system monitoring and improve the preventive maintenance services, improve the service life of equipment, avoid the system temporary failure caused by the business interruption problems, reduce downtime downtime.

Asset Management Services

Relying on the Phegda System independently developed by Damon, realize the remote monitoring of project equipment assets, collect and analyze the operation data of key equipment during project implementation, determine the priority of alarm, find the relationship between shutdown inducing factors, understand the overall on-site asset operation status and realize on-the-spot maintenance based on big data and advanced algorithms, thus extending the asset life.

Regular Equipment Inspection Service

Provide customers with regular equipment inspection services, timely find potential trouble, and take preventive measures, reduce the frequency of equipment trouble, and ensure the good state of equipment and the stable operation of system.

System Extended Warrant

After the system is guaranteed, the extended warranty service shall be carried out according to the customer's needs to continue to ensure the normal maintenance of the equipment.

Relocation Service

According to the relocation needs of customers' warehouses or distribution centers, provide equipment dismantling, identification, packaging, transportation, system installation, commissioning and other related whole process services to ensure the relocation work of the whole system in a short time.

Upgraded Service

The customer's business is constantly changing, when the original system capacity cannot meet the customer's requirements, upgrade the existing system and provide system optimization solutions, including equipment hardware replacement, electrical system, software system iteration and other related services, so that the system can better meet the customer's future business development needs.

Original Spare Parts

In order to ensure the timely replacement of spare parts in case of system failure, Damon's service engineers can help customers easily order high-quality original spare parts, deliver and install them in time, and solve various technical and procurement problems for customers. All original spare parts are selected according to strict standards to highlight Damon's competitive advantage while ensuring system reliability. With the continuous upgrading of the system, the iterative service of original spare parts is provided to prolong the service life of the system.

Other Equipment Services

Services provided by the Third Party not Damon Equipment

In the future, the scale of Damon Technology service team will continue to expand. With the increase of project ownership, engineering technology service will become one of the important development directions of the company. Damon will continue to integrate resources, expand the coverage of service network and enhance the timeliness of services; continue to improve the comprehensive quality of service personnel and provide customers with more timely and professional services; While meeting the customer's demand for the whole package service of logistics storage equipment, the customer's project transformation demand shall be systematically connected in a series of scheme planning, project implementation and after-sales service.

Share to: